BASICS is a series of insights from the project work conducted by Topmotors on efficient motor driven systems and provides an overview of the most important elements for successful energy efficiency improvement in an industrial or service company.

Ein elektrischer Antrieb, z.B. in einer Lüftungsanlage im Dauerbetrieb, kann beträchtliche jährliche Energiekosten verursachen. Mit dem Einsatz von energieeffizienten Antriebssystemen können Energiekosten langfristig tief gehalten werden. Dabei ist es wichtig, die effizienten Komponenten des Antriebssystems im Hinblick auf den tatsächlichen Bedarf gut aufeinander abzustimmen. So können ein hoher Gesamtwirkungsgrad und tiefe Energiekosten erzielt werden.

Optimising electric drive systems is a challenging undertaking. Process demands on drives are constantly changing, depending on the order backlog, the day of the week or the season. Performance measurements provide a good overview of the current use of motors. However, they offer a limited snapshot in time and are often not suitable for optimising a drive system for maximum effect. As a result, a possible redimensioning of the drive system is often not detected.

Nowadays, frequency converters (FCs) are a simple, reliable and relatively inexpensive solution for speed variation in electric motors systems. Thanks to vastly improved operation and pre-programmed «intelligence», FCs have become a regular mass product. Their use offers a host of benefits and can also boost energy efficiency in many cases. However, FCs also cause effects that must be taken into account. In addition to the frequently cited harmonics, there is also an effect that can mechanically stress motors and at worst lead to a premature defect: Bearing currents.

Electric Motor Driven Systems (EMDS) are responsible for 53% of electric energy use worldwide. They drive pumps, fans, compressors and also transport, process and infrastructure systems.

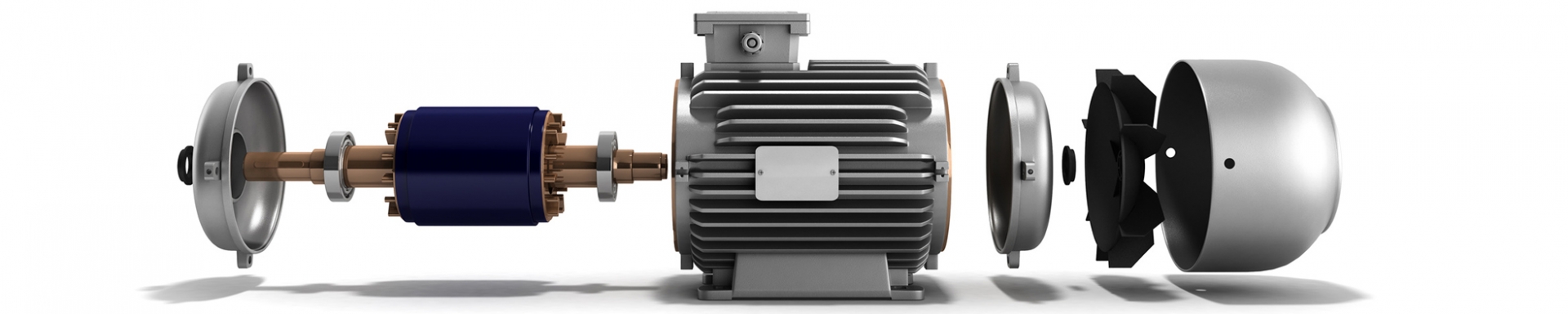

In order to make mass produced rotating machines in a global market easily available and their performance comparable, standardization is the key. Not only geometrical and electrical properties but also energy performance is standardized.

Cooling systems are an important element in many companies in Switzerland. Cooling capacity failure or decrease generally has an immediate effect on production, quality and storage – for manufacturing and chemical processes, food processing and logistics. At the same time, cold generation is an energy-intensive process with complex, expensive refrigeration networks and cooling units using sensitive substances (refrigerants).

Compressed air is practical and reliable. Leaks in the network often get unnoticed and are not perceived as a problem. What is often overlooked is that compressed air is a very expensive energy source that should be handled carefully. Every cubic metre of air goes through a series of processes before it meets the quantity, pressure and quality required for the compressed air network. The use of waste heat from the compressor increases the total efficiency of the compressed air system.

In industry, where economy is everything, energy-related improvements are only implemented if they are worth it and the payback times are short. Much of the potential for improving energy efficiency is never recognised because energy seems to be unimportant, companies lack the relevant expertise and pay little attention to it. Minimum requirements have proved successful in many countries, i.e. from a certain point in time, inferior products (motors, pumps, fans, etc.) are no longer available on the market.

BASICS No. 06 deals with new motor-driven technologies that are currently being used in industry. It provides information on various motor systems such as asynchronous, permanent magnet and synchronous reluctance motors. In addition to typical efficiencies of the various technologies, advantages and disadvantages are also described.

Variable frequency drives (VFD) are used to continually and electronically regulate asynchronous motors to lower and higher torques, depending on the application. Modern standard motors can be operated in conjunction with a VFD without any problems. Older motors, on the other hand, are not always compatible with VFDs due to electric and mechanical reasons.

The process of carrying out maintenance on motor driven systems does not begin when a motor fails or is shut down for a service. Instead, maintenance must be initiated long in advance. The best time to think about maintenance and replacement is while the motor driven system is still running smoothly.

Electric motor driven systems run much longer than their operating life expectancy of 10 to 20 years, according their output size. Their bearings are regularly greased and repaired and even their stator copper wiring is ventually rewound at considerable cost. But, even with careful maintenance, old motors can never reach the efficiency of modern IE3 Premium Efficiency motors.

Many motor systems can be improved with very low payback times.

The results of the cost benefit analysis of motor driven systems in a machine factory in Switzerland show that many big machines with around two years payback generate substantial electricity and cost savings.

Proper coordination of the individual components in one system with the necessary dimension for the process actually required are decisive in creating an efficient motor driven system: pressure, temperature, flow, etc. Many old motor driven systems that are oversized and have poorly coordinated components are still being used in industry and in large facilities. They consume an unnecessarily high amount of electric energy.