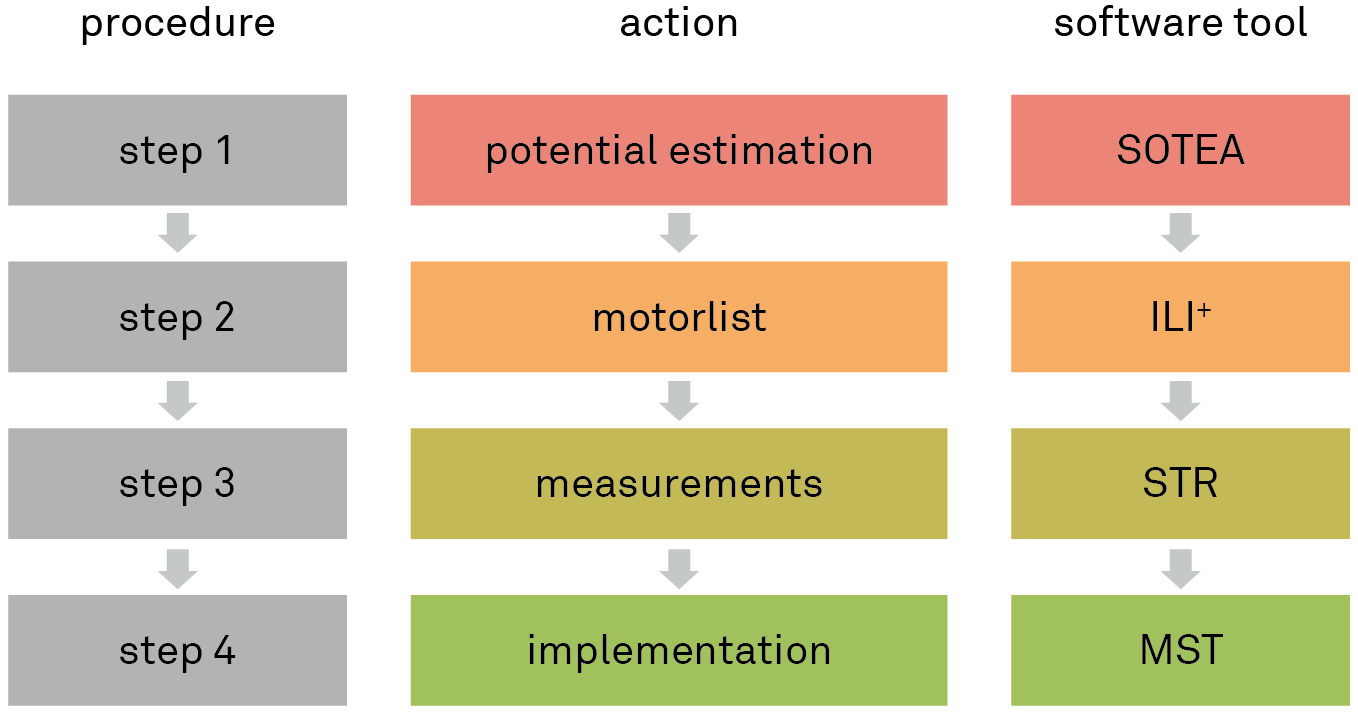

Going from the first estimate to the detailed analysis - Topmotors adopts a progressive approach and has developed a 4-step audit method for systematically analysing motor driven systems in factories: the Motor-Systems-Check.

- Estimating the savings potential

The Topmotors Tool SOTEA generates a rough estimate after the first overview based on minimal data from the operation under review and shows the proportion of motors in the total energy consumption. An initial estimate of the potential savings of the motors is then carried out working. - List of motors

Your factory has hundreds or thousands of motors - where should you start? The second step of the Motor-System-Check includes drawing up a list of motors. It covers all the relevant drives and is used to identify potentials. The Tool ILI+ (Intelligent Motor List) tool analyses the recorded motor driven systems based on the following criteria e.g. age, nominal output and operating hours, and estimates the savings potential through the use of more efficient motors and the use of frequency converters. It also helps to select the motor driven systems that have the highest savings potential. - Measurements

After the motor driven systems with the highest potential have been identified, specific measurements are taken on selected motors. The Standard Test Report (STR) helps to evaluate the data collected from the measurements and to describe the current ACTUAL state. In addition to this, the STR enables a comparison of the ACTUAL state with a possible TARGET state and calculates the savings per year as well as the pay back time. The return on investment and cost-effectiveness (Rp./kWh) are calculated on the basis of the total costs for the implementation. - Implementation

In a final step, the efficiency measures are implemented in cooperation with manufacturers, specialists or suppliers. The Motor Systems Tool from our colleagues at the Danish Technological Institute can be used to support the design of the improved motor driven systems. It shows the performance and efficiency at various points in the load status and determines the overall efficiency of the entire system.